Magnetization Process in Magnet Manufacturing: Turning “Slugs” into Powerful Magnets

Magnets might seem like they’re always magnetic by nature, but in industrial production, that’s not the case. In fact, magnetization is usually one of the final steps in making a permanent magnet.

Magnets (especially strong rare-earth magnets like neodymium) go through mining, alloying, pressing, and heat treatment steps without exhibiting any magnetic pull. These unfinished magnets, often called slugs or blanks, have their internal grain structure aligned in a preferred direction during pressing, but they won’t actually stick to metal until their magnetic properties are activated in the magnetization process. In this blog, we’ll explain how the magnetization process works.

Magnet Manufacturing and the Role of Magnetization

Modern permanent magnets are engineered products – their magnetic strength and orientation are carefully designed, rather than being an inherent result of the material. By the time a magnet reaches the magnetization stage, it has already been through several key steps.

First, raw rare-earth material (like neodymium, iron, and boron) is melted into an alloy and cast into ingots, then ground into a fine powder. Next, the powder is pressed in a mold while an external magnetic field is applied to align the particles in one direction. This creates an anisotropic magnet, meaning it has a preferred direction of magnetization. (Most high-performance magnets are anisotropic, which ensures they can later be magnetized very strongly in the intended direction.)

After pressing, the magnet is sintered (heated) into a solid piece and often machined and coated for protection. At this stage, the magnet has a defined shape and an internal grain orientation (its north-south pole direction is set), but it still has no significant external magnetic field – it’s essentially inert. Only after exposure to a powerful external magnetic field in the magnetization process will the magnet reach its full magnetic potential.

The Magnetization Process

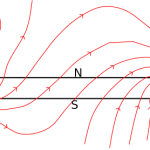

During magnetization, the magnet slug is placed inside a specialized device called a magnetizer (or magnetizing coil). When the magnetizer is energized, it produces a very strong magnetic field that forces the magnetic domains in the material to align and “lock in” along the preset orientation, activating the magnet’s field.

In other words, the magnetizer turns the slug into a magnet by saturating it with an external field. This is typically done by charging a high-voltage capacitor bank and discharging it through a tightly wound coil or fixture around the magnet.

The resulting magnetic field can be extremely intense but very brief. For example, many neodymium magnets require on the order of tens of thousands of oersteds (often 30,000–50,000 Oe, equivalent to 2.5–5 Tesla) to fully magnetize.

Generating such a field continuously is impractical, so magnetizer machines create it in a quick pulse. By applying roughly 2 to 2.5 times the magnet’s coercive force in a short burst, the material is driven to saturation (full magnetization).

After this process, the once-inert slug now exhibits a strong north and south pole as designed.

Understanding the magnetization process

Understanding the magnetization process is crucial for any business utilizing high-performance magnets. While it may be one of the final steps in production, it's also one of the most critical—turning a carefully engineered, directionally aligned slug into a fully functional magnet. Whether you're assembling sensitive electronics, designing magnetic couplings, or managing logistics for bulk shipments, understanding when and how magnetization occurs enables you to make smarter, safer, and more efficient decisions.

Shop Online and Follow Us to Learn More

At Apex Magnets, we offer tailored B2B solutions—including unmagnetized slugs, custom magnetization patterns, and technical guidance—to ensure your magnets perform exactly as needed. Explore our B2B services to learn more or contact our team to discuss your specific application.

We offer a vast selection of magnets, so be sure to browse through them to find the perfect options for your specific needs. Subscribe to our monthly newsletter! You’ll be among the first to receive notifications about our latest blogs and our latest magnet deals.

If you need further assistance or have questions, please don't hesitate to contact us.

Magnets can be dangerous. Neodymium magnets, especially, must be handled with care to avoid personal injury and damage to the magnets. Fingers and other body parts can get severely pinched between two attracting magnets. Bones can be broken by larger magnets.

Visit our Magnet Safety page to learn more.