What Are Diametric Magnets and When Should You Use Them

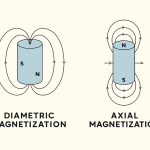

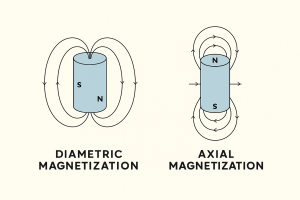

While most magnets are magnetized through their length or thickness, diametric magnets are magnetized across their diameter or width, as in diametric blocks. This creates a distinct magnetic field pattern that opens up new possibilities for industrial applications. If you need more help visualizing the difference, view our helpful video about axial vs. diametric magnets here.

If you’re working on designs that require precise rotation sensing, smooth couplings, or specific directional alignment, it may be time to consider diametric magnets. In this blog, we’ll explain what they are, how they behave, and why they’re gaining traction in advanced sensing and motion control systems.

What Is a Diametric Magnet?

A diametric magnet is typically cylindrical and magnetized across its diameter, meaning its north and south poles are located on opposite curved sides, not on the flat ends like an axially magnetized magnet. This is distinctly different from a radial magnet. Radial magnets are magnetized so that the entire inner surface is one polarity and the entire outer surface is the opposite.

If you were to cut a radial magnet in half, each surface would still maintain uniform polarity. In contrast, cutting a diametric magnet in half would result in two pieces—each with a north pole on one side and a south pole on the other—because the magnetization runs directly across the curved face.

Diametric magnetization creates a lateral field pattern, meaning the magnetic field exits one side of the diameter and re-enters on the opposite side. This unique field geometry can be advantageous in rotational applications, particularly when paired with sensors that rely on angular position detection.

Diametric Magnetization vs. Axial or Radial

Most cylindrical magnets are axially magnetized, meaning the field runs through the flat faces. This arrangement is ideal for pulling force in mounting applications, but not for rotation or lateral field sensing.

Diametric magnets, by contrast, provide:

- A strong lateral field pattern across the diameter

- Consistent rotational field symmetry, useful for angle and speed detection

- Uniform performance around the magnet’s axis, enabling 360° sensor readings

Radial magnets (often ring-shaped) also offer a circumferential field but are more complex and expensive to manufacture compared to simple diametric magnetization.

Where Are Diametric Magnets Used?

Magnetic Rotation Sensing

One of the most common uses of diametric magnets is in angle sensing. When coupled with a Hall effect or magnetoresistive sensor placed near the rotating magnet, the changing field direction can be used to detect angular position or speed with high resolution.

Applications include:

- Robotics and automation

- Motor position control

- Joystick or encoder feedback systems

- Medical devices with rotary motion

In fact, a recent tech briefing by Daniel A. Baker of NVE Corporation (as seen in Magnetics Magazine) highlights how diametrically magnetized magnets are ideal for magnetic angle/rotation sensing. His article explains in detail how the stable, symmetric field lines of a diametric magnet make it highly compatible with advanced magnetic sensors. Read more here.

Magnetic Couplings

Diametric magnets can be used to create low-contact magnetic couplings that transmit torque between shafts or gears. This is especially helpful in fluid-handling systems or applications where mechanical contact needs to be minimized to reduce wear or contamination.

Alignment & Latching Systems

The lateral field of a diametric magnet can offer more directional control when aligning parts or creating magnetic latching systems. The field pattern may also make predicting alignment behavior in mating assemblies easier.

Custom Magnetic Assemblies

In applications like miniature robotics, haptic devices, or multi-axis motion systems, diametric magnets can be customized and embedded into housings to create low-profile, precision field sources.

What to Consider When Sourcing Diametric Magnets

If you’re considering diametric magnets for a project, keep the following in mind:

- Material: Neodymium is often used for high-performance applications, but ceramic may be suitable for lower-cost sensing.

- Coating: Choose a corrosion-resistant coating for moisture-prone or medical environments.

- Tolerance: Dimensional precision matters in sensor placement and rotational balance.

- Magnetization pattern: Verify true diametric magnetization—cylindrical shapes are not always standard.

Diametric magnets aren’t new, but they’re gaining renewed attention in today’s sensor-driven and motion-sensitive designs. Whether you’re developing a rotary encoder, refining a magnetic coupling, or building smarter feedback systems, their unique field orientation may offer the edge you need.

At Apex Magnets, we carry diametrically magnetized rings, discs, blocks, tubes, and cylinders.

Do you have questions about sourcing diametric magnets for your application? Apex Magnets can help you identify the right size, grade, and configuration for your build.

Contact us for recommendations, custom quotes, or technical support at www.apexmagnets.com/b2b